News

Pay attention to the latest developments in the cable harness industry.

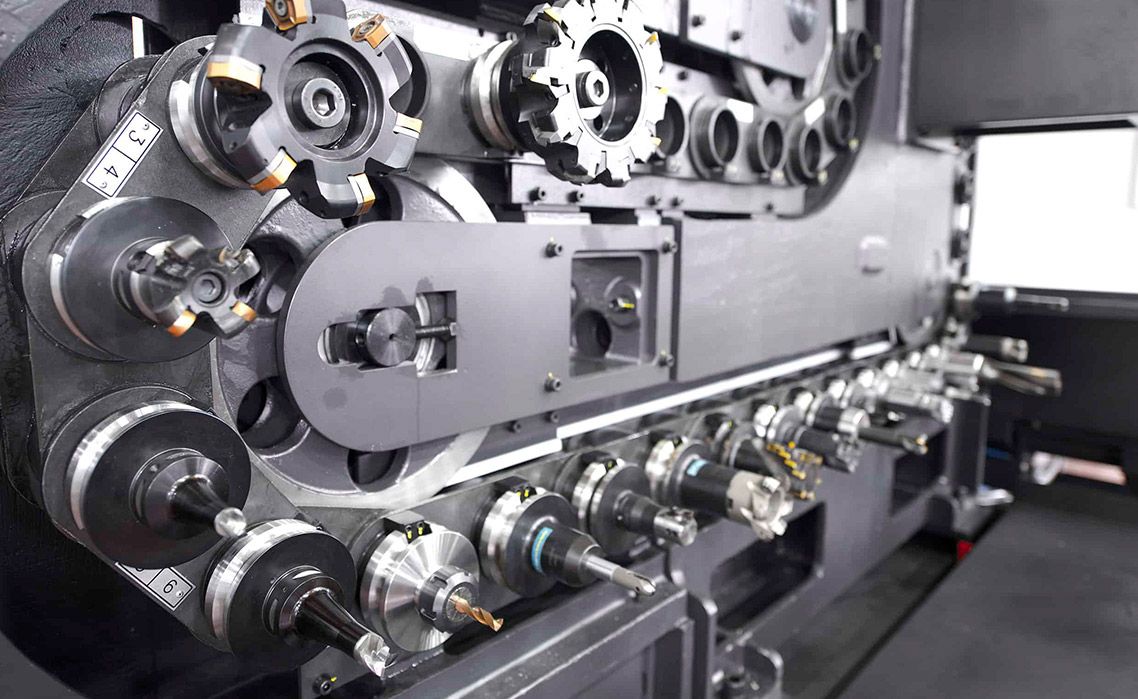

Machine tool equipment cable selection principle

22 March 2022

Cable selection principles

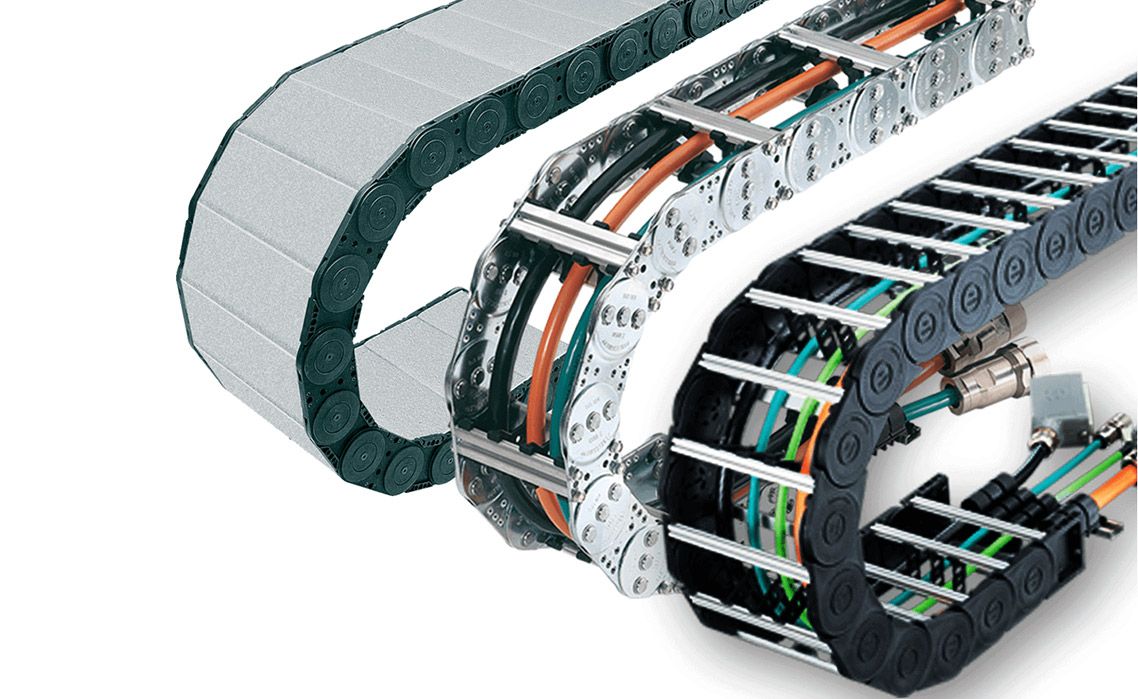

When selecting machine tool equipment cables, the following factors need to be considered comprehensively:

- Load current: Load current is one of the main factors in cable selection. Typically, the cross-sectional area of the cable should be equal to or greater than the load current. This avoids overloading and overheating of the cable, which can cause machine failure.

- Wire length: The length of the cable is also one of the factors that affect the choice. The longer the cable length, the greater the cable resistance, so a cable with a larger cross-sectional area should be selected to reduce the losses caused by the resistance.

- Ambient temperature: Machine tools often work at relatively high temperatures, so the selected cable should have good temperature resistance to ensure the normal operation of the machine. In general, the cable selection can be based on the maximum allowable operating temperature in the product description of each cable specification.

- Voltage: The rated voltage of the cable is also one of the factors to consider in the selection process. If the input voltage of the machine tool equipment is relatively high, then it is necessary to choose a cable with a higher rated voltage.

How to choose a cable cross-section

According to the above cable selection principle, the method of selecting the cable cross-sectional area is as follows:

- Calculation of load current: The load current usually needs to be calculated by the circuit diagram of the machine tool.

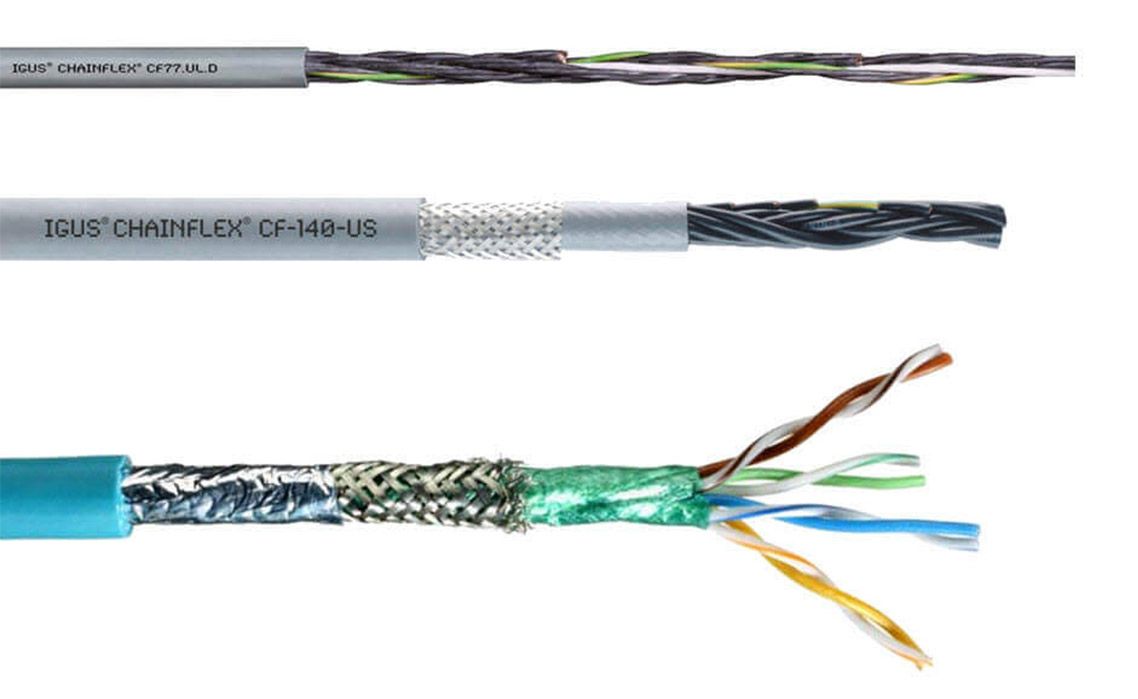

- Selection of cable material: In general, the cable of machine tool equipment adopts copper or aluminum wire.

- According to the wire length and the ambient temperature of the cable, refer to the wire current load meter (usually found in the product manual of the wire) to select the cable specifications that meet the requirements.

- Comparison result: Compare the load current of the selected cable specification with the actual load current this time, if the cable load current is less than the actual load current, you need to replace the cable with a large cross-sectional area of the cable, or add the number of cables to ensure the safety performance of the cable.

Conclusion

The size of the machine tool equipment cable needs to be considered comprehensively according to factors such as load current, voltage, and wire length. Choosing the right cable can ensure the normal operation and service life of the machine. When choosing a cable, it is necessary to carefully compare the cables of various specifications and choose according to the actual situation.